Your source for parts, service and operator PDF manuals

Here are the Hyster forklift error codes and the Yale forklift error codes. They are the same on both brands of lift truck.

Unicarriers Forklift Error Codes

Unicarriers Forklift Error Codes - TCM, Nissan - Warehouse IQ

Unicarriers owns the Nissan forklift brand, as well as the TCM forklift brand. We list Unicarriers forklift error code faults and their solutions.

Yale and Hyster Pallet Jack Error Codes

Error Codes for Hyster W40Z or Yale MPB40-E pallet jack Error: no LEDs or LCDs on What the issue is: Inoperative Cause of Problem: B+ and/or B- missing at controller, defective battery charger, or defective battery charger. What to do: Ensure the battery is connected, the key switch is on, and the brake override circuit is in the run position...

Clark Forklift Parts

Order Clark forklift parts using our material handling truck experts. Let us know your lift truck info and we will source the parts you need.

Raymond Forklift Error Codes

Handy Raymond forklift error codes list to reference when your Raymond lift truck goes down. Keep it handy to diagnose troubles with your industrial truck

Caterpillar Forklift Error Codes

Looking for Caterpillar forklift error codes? We've made a list of them.

5 Ways Custom Access Platforms Impact Warehouse Operations

Custom access platforms offer warehouse employees safety, portability, and ease of use without expensive equipment or hazardous ladders.

Forklift Ramp Incline Calculator

Use this online forklift ramp calculator to figure out the necessary slope needed for your forklifts so they can navigate your warehouse safely. As a rule most forklifts can safely travel on a ramp with a gradient between 5% and 12.5%.

Pallet Space Calculator

Use this pallet space calculator to calculate how many pallets you can fit in your warehouse.

7 Clever Ways To Increase Warehouse Storage Capacity

If physically extending a warehouse is not be an option, it's still possible to maximize the space available by implementing these innovative tips.

Pettibone Forklift Manual – Download PDF

Our Pettibone forklift manual inventory includes access to some popular forklift manuals you need to repair your lift truck.

Forklift error codes for Caterpillar

Look up forklift error codes for Caterpillar. We also have error codes for other forklift brands.

Forklift Error Codes

Find the meaning of your forklift error codes. We have manuals that lists them for Yale, Hyster, Nissan, Mitsubishi, Toyota, Raymond, and more.

How to find Hyster forklift serial number

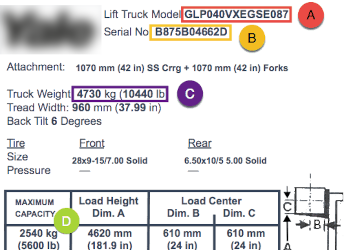

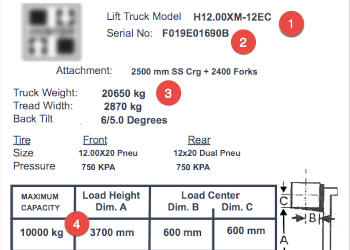

The best way to locate the serial number on a Hyster forklift is to find the nameplate, which is also called a data tag. This handy metal plate is affixed to your forklift and displays various information about your forklift truck. The forklift nameplate.

How to Find a Yale forklift serial number

How to find a Yale forklift serial number. Easy step by step instructions on how to locate the data late on your Yale lift truck.

How to Find a Hyster® Forklift Model or Year

In this Hyster forklift serial number guide, you'll learn how to find a Hyster lift truck data plate and determine the year of manufacture or the model number.

Stand Up vs Sit Down Forklift & What is the difference?

There are two kinds of counterbalance forklift trucks. Stand-up and Sit-down. We first examine what counterbalance truck is, and then get to the differences in types of counterbalanced forklift trucks.

Forklift horns – Top replaced forklift parts

Forklift horns – Top replaced forklift parts

Here are some of the best sources to find forklift horn component parts for your lift truck. The ultimate resource to find replacement forklift horns.

How much does a forklift weigh?

Want to know how much a forklift weighs? Learn the weight of the most common forklifts.

Best pallet racking protector

Learn about the best pallet racking protector of each type for a warehouse. We examine the best products designed to protect pallet rack from damage.

Hyster Forklift Parts Manuals

Here is instant access to the most common Hyster forklift parts manuals. We have the PDF you need to fix your lift truck.

Free forklift training manual resources

A great list of forklift training manual resources. Use these free PDF guides to develop your own training manual for your warehouse.

What is the Crown Equipment Corporation?

Learn about the Crown Equipment Corporation and what forklifts and materials handling equipment it makes for the warehouse industry.

Forklift manufacturers

Here are the top forklift brands and the forklift manufacturers that build them. Each has a link to an info page about the lift truck companies.

Forklift tires: Difference between pneumatic and cushion tires

Learn about the different types of forklift tires. Discover the pros and cons of pneumatic versus cushion tires for lift trucks. Plus how they are used.

The truth about lithium ion batteries for forklifts

If you are a warehouse manager that walked the floor at the materials handling show Promat in the spring of 2017, you may have noticed the number of vendors touting lithium ion batteries for forklifts. The technology is relatively new for forklifts, and yet there are many questions warehouse managers are asking about their use in a

How to get a forklift drivers license

Follow these steps on how to get a forklift drivers license. You can get certified within a few days or a couple of weeks. Learn the process in this article

Pallet jack wheels – All about replacement casters

Pallet jack wheels come in all shapes and sizes and brands and models. Don't forget about checking your pallet jack bearings and axles too.

Order Picking Strategies For a Warehouse

Here are some of the best order picking strategies that will maximize picking efficiency of your pick lines, system and processes. Learn how to pick faster.

Warehouse Space Calculator

This warehouse space calculator will estimate the square feet your operation will need to for the number of pallets you need to store

Pages